Longden Steel makes inroads into structural steel engineering

HARARE – The steel and metal sector is always changing, but the demand for their products has remained consistent in recent years. However, if you don’t have the necessary tools and information, your ambition of owning a great steel manufacturing company will be shattered. Always keep an eye out for market changes as well as the needs of your client base or target market. Operating a business in this challenging environment will take hard work and commitment. Incorporated in 1996, Longden Steel has managed to not only dominate the steel industry but to diversify in order to meet the ever-changing needs of the market.

Products and Services

Reinforcement steel, meshwire, shepherd crooks, brick force, threaded bolts, and stay sets are among the products available. Bolts can be delivered as normal bolts or as non-standard bolts, depending on the customer’s needs. Threaded bolts are used to support subsurface structures and include studs, holding bolts, anchor bolts, and shepherd crooks.

It also uses bending schedules provided by structural engineers to cut, bend, and fix steel reinforcement steel. The accuracy of the bend is maintained by employing Murray & Roberts South Africa’s cutting and bending machinery. During the manufacturing process, the organization maintains strict quality standards and conducts constant inspections.

This is an important part of completing a construction project that calls for reinforcement steel. It provides steel fixing instruction in-house with our own teachers who have over 20 years of expertise in the field. Longden maintains its market leadership in the steel reinforcement industry by providing management and site crews with the necessary knowledge in project management, contract pricing, risk management, business administration, and managerial skills through its ongoing learning program.

The key to quality control is to invest in the correct machinery. Although tools and machines are not inexpensive, they are nevertheless preferable to manual labor since automated machinery allows for fewer mistakes and errors. These minor mistakes, as minor as they may seem, might harm your business, so be cautious.

The engineering and fabrication sector of the company is well-equipped with cutting-edge machinery and technology, allowing employees to complete jobs with the utmost precision. It equips its employees with the most up-to-date tools and equipment so that they can operate as efficiently as possible. The company has also invested in contemporary ICT, high-speed data connectivity, and other communication technologies in order to share information with other manufacturing facilities and keep track of its production goals and progress. It has been able to consistently supply superior steel fabrication and erection solutions thanks to its technical acumen and engineering skills.

Deformed bars

The rebar produced by the company complies with the following standards: BS 4449:2005 and SANS290:2011. It also cuts and bends steel to the specifications of the engineer. Y8 to Y40 are the sizes available. Every delivery is accompanied by a test certificate.

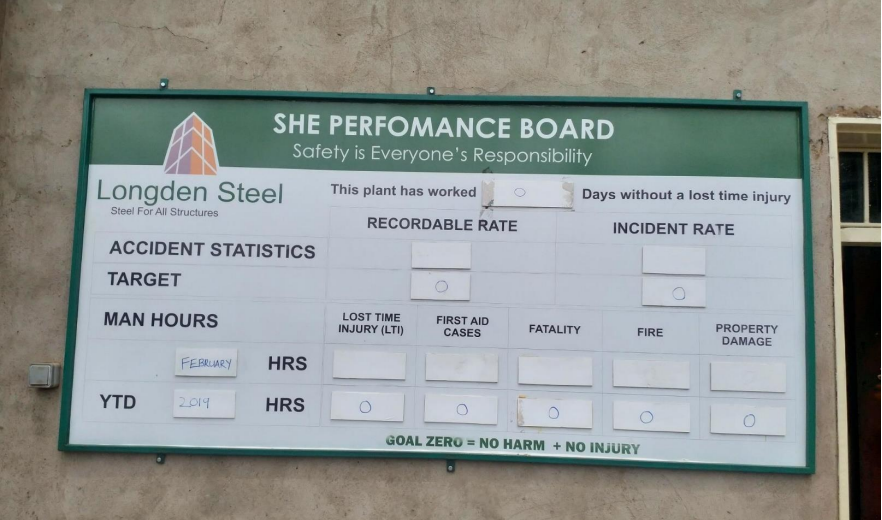

Safety

While the working environment is prone to disasters and accidents, the company remains committed to its strategic pillar of zero harm. It has invested significantly in improving the health and safety of employees at the workplace. While in the workshop and on the job, all of its employees are required to wear full Personal Protective Equipment. It employs a full-time Safety Officer who ensures that all of our machines and motor vehicle fleet are maintained in compliance with our varied clients’ and regulatory safety requirements.

Project Experience

Longden Steel, like every other company in the steel sector, has a solid track record. Due to its extensive technical competence, the company has completed big projects across the country and is the chosen rebar supplier and subcontractor. Some of the projects it has undertaken include the iconic Mbuya Nehanda Statue 2021 (179 MT), the Crown Jewel Project at Murowa Diamonds (739 MT), just to mention a few. Every year, it produces around 5000MT of cut and bent steel. Located at 490 Goodwin Road Willowvale Harare, Longden Steel is headed by a group of qualified personnel. The company is also ISO certified with the Standard Association of Zimbabwe in accordance with ZWS ISO 9001: 2015

Below are key management profiles

Managing Director – Mutsvene John Marangwanda Holds a Bsc Economics Hons Degree from UZ and has vast experience in both the public and private sectors. Has worked before as the Director, Economics in the President’s Office and the Minister Counselor at the Zimbabwe Embassy Luanda and Gaborone. After leaving the civil service, joined Hunyani Paper and Packaging as the Group Purchasing Manager from 1990 to 1996. He then joined Unilever in 1996 as a Buying Manager and had risen to be South East Africa Regional Supply Chain Manager by 2003. In that year he left formal employment to start Longden Steel.

New Business Director – Masimba Marangwanda Masimba holds a Bachelor of Business Administration degree from Solusi University. Masimba joined Longden in 2007 as a New Business executive for three years before being promoted to New Business Manager were, he heads the department responsible Construction and Mining.

Finance & Administration Manager – Tapiwa Marangwanda Tapiwa is responsible for finance and administrations functions of Longden Steel. He joined Longden Steel in May 2004 as an Assistant Accountant rose to become an Accountant in 2006, assigned to head the Supply Chain department in 2007 and was reassigned to head the Finance department in 2016. He holds a Bachelor of Commerce Honours Degree in Accounting from Midlands State University and a Diploma in Purchasing and Supply with the Chartered Institute of Purchasing and Supply.