Proplastics toughens zero-harm policy on workplace safety after recording 4 LTI

By Almot Maqolo

HARARE – The term ‘safety’ in the built environment often refers to the state of being protected, or safe, from risks and other unfavorable events.

Because construction is one of the most dangerous sectors to work in, it is critical to maintain positive control and management of hazards and risks in order to reach a high level of safety, which is often a legal necessity.

Construction workers are exposed to a variety of risks, including falling from rooftops, unprotected machinery, being struck by heavy construction equipment, electrocutions, silica dust, and asbestos.

As part of their safety management programs, construction businesses employ a variety of safety procedures, with an increasing emphasis on instilling a safety culture throughout the organization.

At Proplastics, the concerned stakeholders are always engaged in improving health and safety measures for both parties.

The Zimbabwe Stock Exchange listed firm manufactures and markets plastics pipes and fittings, specializing in the production of polyvinyl chloride, high-density polyethylene, low-density polyethylene pipes and related fittings.

With the benefits of a focus on safety being quite obvious, it is time to take a closer look at Proplastics’s construction site to see if it is doing all it can to protect workers. “The business recorded four Lost Time Injuries (LTI) with the severity rate at 10 compared to 4.4 in prior year,” the group said in its 2021 annual report.

“Most of the injuries were outside the company premises. The business will continue to rigorously work on this area as our policy remains zero harm.”

However, the company remains certified to the following key international compliance standards for its processes: ISO 9001:2015 (Quality Management System), ZWS ISO 14001:2015 (Environmental) and ISO 45001:2018 (Health and Safety). Also, SAPPMA (Southern African Plastics Pipes Manufacturers Association).

In 2021, it completed the migration to the new standard ISO 45001:2018 from the old Standard OSHAS 18001:2007.

“This standard has an improved risk-based thinking approach,” it said.

Companies need to make safety requirements a condition of employment to foster a culture of safety. Regularly hold training sessions to ensure that everyone understands your safety advice, and recognize employees who consistently put safety first.

Even if no incidents occur, an unsafe workplace poses a threat.

Accidents on the job site could raise the overall cost of your project. Damage to equipment or supplies is common, and your expenses will rise as a result.

Worker’s compensation claims might raise total operational costs for injured personnel. A lawsuit is likely if the person who was hurt was not employed by the building company. Maintaining a safe construction site reduces this risk, allowing your project to be completed on time and on budget.

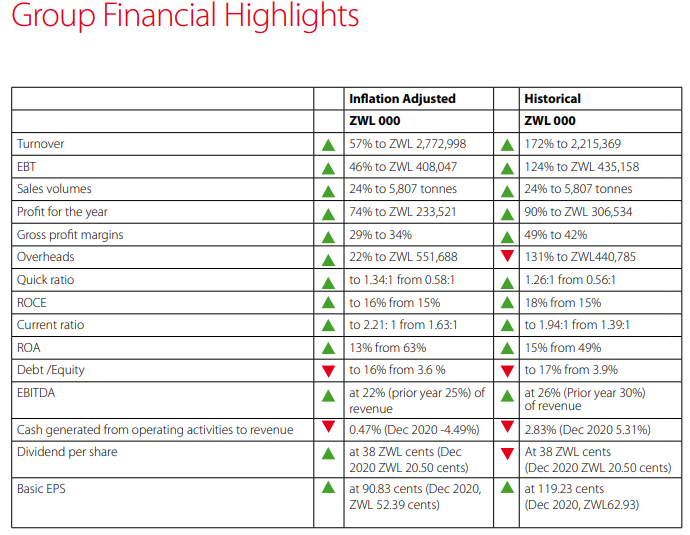

As of the financials, the group posted a gross profit of ZWL$933 million compared to ZWL$515 million in the prior year. Overheads were kept to a minimum, resulting in EBITDA of ZWL$624 million, up from ZWL$442 million the previous year, and profit before tax of ZWL$408 million, up from ZWL$279 million the previous year.

The statement of financial position remained strong with total assets amounting to ZWL$3.46 billion. The recently constructed factory is now fully functional and the attention has shifted towards beefing up working capital to sweat out the investment to its installed capabilities. It closed the year with cash and cash equivalents of ZWL$328 million.